Organic Waste

An untapped resource to be turned into a valuable product!

In the post-fossil world, biomass will be a valuable source of energy and materials. Its use has to be carefully optimised, considering also non-energy aspects such as biodiversity or nutrient management. Frédéric Vogel’s team at PSI and FHNW collaborates with industry partner TreaTech to bring the technology of catalytic hydrothermal gasification of organic waste to market.

As we discussed on the ‘Conversion & Storage’ page, a key ingredient for success in the future energy system is efficiently transforming energy from one form into another. How about we now open the playing field and explore what other starting points for energy conversion we can find?

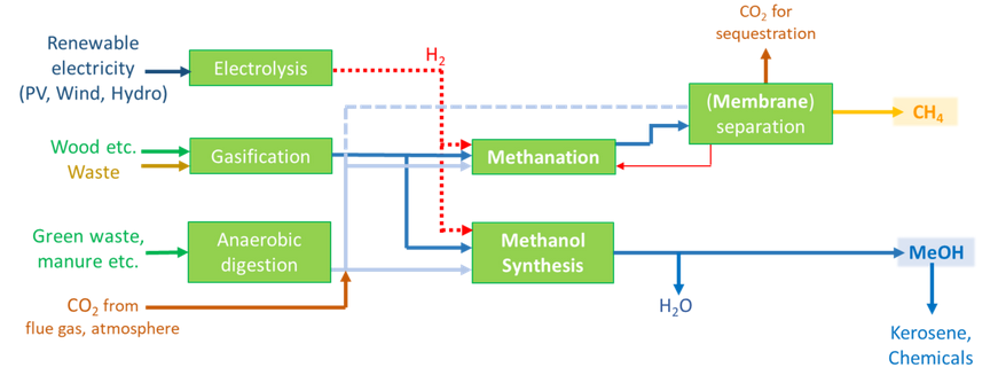

Indeed, energy can hide in undervalued places: In the spirit of recycling, circular economy & co., researchers at the Paul Scherrer Institute (PSI) are giving organic waste a second life. One aim is to produce biogas which can serve as an alternative fuel in the future mobility sector. Several routes are being explored here, including hydrothermal gasification of waste. Such processes are also referred to as Power-to-Gas, i.e. are a prime example of the Power-to-X mentality of the future energy system, which you can learn more about at the page about power grids.

After gasification, biogas can then be further processed by removing higher hydrocarbons, sulphur compounds and further impurities, until one is left with hydrogen, methane and carbon oxides. These can be further converted into liquid fuels, similar to the conversion of syngas into green kerosene. If you like efficiency, you might also enjoy the work of the Catalytic Process Engineering Group, which makes sure we make the most of the waste. Or alternatively, organic waste can also be turned into biogas fuel by collaborating with microorganisms through anaerobic digestion!

Apart from producing biofuels for mobility, organic waste also has the potential to power another important sector: Over on the industry page, we discussed how heat pumps hit their limit when it comes to decarbonising high temperature industrial processes. Yet these are crucial to producing many goods, from food to steel and cement. Biogas could provide a renewable solution in this hard-to-abate sector since it is a direct replacement for burning natural gas to achieve these high temperatures.

The WWF also points out additional benefits of biogas: By removing significant amounts of animal manure and food waste from the environment, we can prevent nitrogen pollution and runoff into water resources. Further one can argue that biogas also helps mitigate methane emissions: Otherwise, the methane would have escaped from landfills and waste heaps directly into the atmosphere. When combusting biogas, however, the methane is converted to CO2, which is up to 34 times less potent as a greenhouse gas.

At the end of the day we should, of course, remember that the point of researching biogas is not for us to produce more waste. Rather you can think of it as one route of making use waste that already exists. And to reduce CO2 emissions, we must try all routes!