Industry

Tailor-made heat pumps deliver medium temperature process heat!

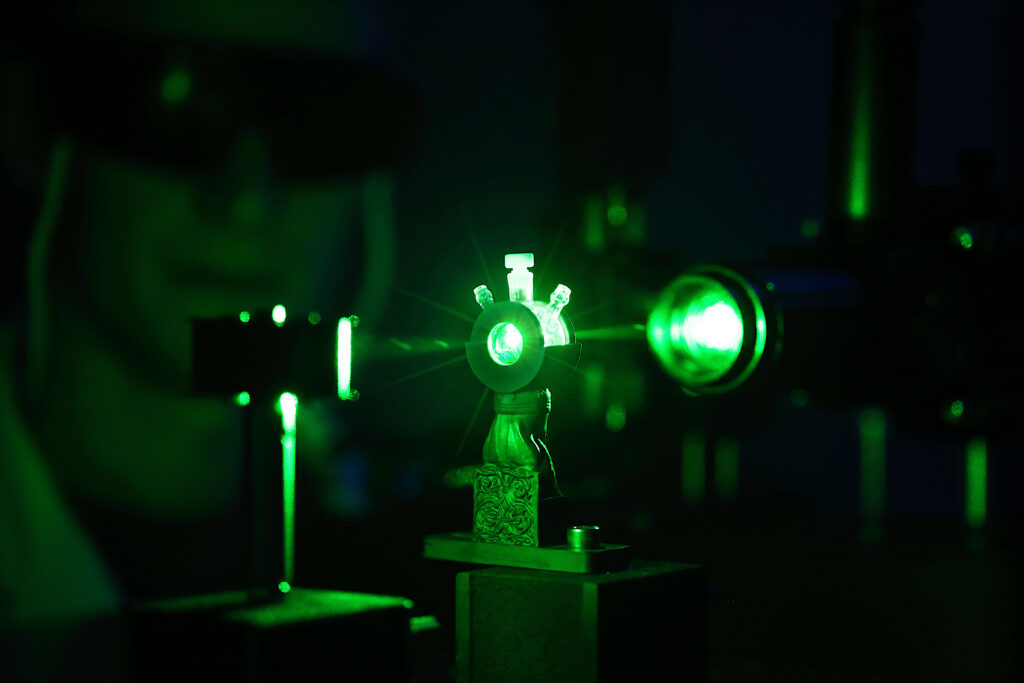

Whenever possible, the supply of industrial process heat will be electrified, just like the heating and mobility sector. This requires efficient, high-temperature heat pumps. Researchers in André Bardow’s lab use Raman laser spectroscopy to quickly find optimal mixtures of working fluids.

When it comes to decarbonizing our present society, you probably think most about your own daily life. That’s great – you can take immediate action! However, 20% of total energy consumption in Switzerland comes not from households, but industry. Take a guess what industry needs energy for: Is it lighting up offices? Keeping employees warm? Nope, 55% of industry energy consumption goes into so-called industrial process heat.

The reason why process heat is so significant is that it encompasses a wide range of activities: From drying paper, preparing food products, to refining surfaces (e.g. electroplating, enamel) and even melting raw materials such as glass or metals, no wonder industrial process heat consumed 86 PJ of energy in 2016, for example. In 2016, this corresponded to roughly 2.5 million tonnes of CO2. What can we do to get this number down?

To answer that question, let’s first get an overview of what range of temperatures is needed in these industrial processes. To start with, there are some processes such as washing or electroplating for which temperatures of under 100deg suffice. These can be achieved with high temperature heat pumps that use temperature differences from ambient air, water or ground sources, which is then transferred to a liquid such as water making use of thermodynamic principles to compress a fluid to raise its temperature. On the other end of the spectrum, there are processes such as cement production that require extremely high temperatures of up to 1500deg. No chance for heat pumps here! Instead, we will need to switch to concrete with lower cement fraction, consider other fuels such as wood instead of coal and capture the CO2 we cannot avoid.

In the middle, however, lies a temperature range of 100-200deg that can still be achieved using heat pumps… But you need to be smart! This is exactly the sweet spot that Professor André Bardow’s group at ETH specializes in. His team investigates the efficiency of heat pumps from the molecular to the systems level.

Not only do they take the theory of thermodynamics back to the drawing board and consider how zeotopic mixtures make so-called Rankine cycles more efficient. In addition, they use computer-aided molecular design to digitally explore new materials, choose the right molecules for their heat pump working fluids and finally test these in laboratory experiments! Shoot them an email to see Raman spectroscopy in action!