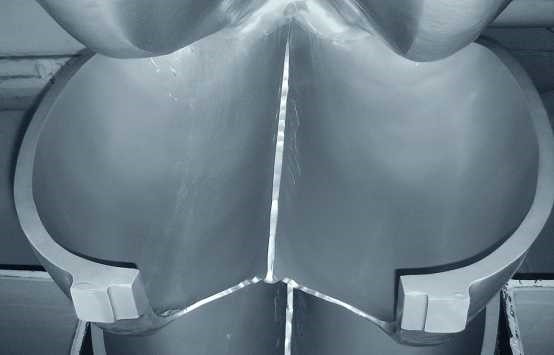

Runners of various hydroelectric turbines

Pelton turbines are typically used in hydropower plants that have a high reservoir water level (high-head plants). A jet of high-velocity water hits the buckets, which turns the turbine wheel. Francis turbines are generally used in medium- and high-head hydropower plants. Unlike Pelton turbines, they are fully submerged in water. High-velocity water flows into the turbine blades in a spiral manner, which turns the turbine wheel.

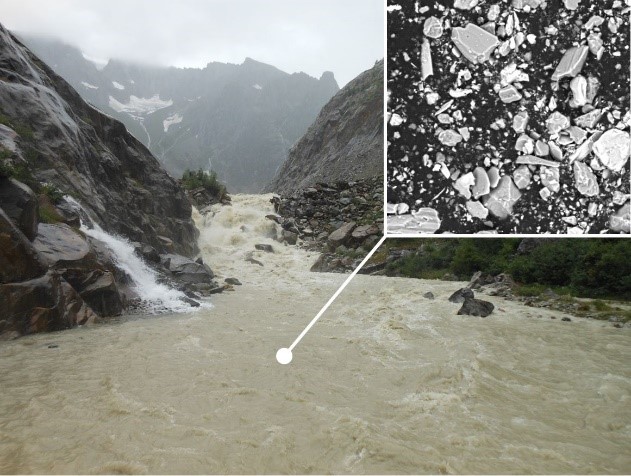

The Laboratory of Hydraulics, Hydrology and Glaciology (VAW) at ETH Zurich and its research partners from other universities and industry conduct a variety of research projects related to hydropower. Although hydropower is a proven technology, it can still be further improved by making use of advanced numerical simulations, novels sensors and comprehensive data evaluation. In Switzerland, hydropower has a central role for the production and storage of electric energy. In mountainous regions as the Alps, Pelton turbines are particularly important and the handling of fine sediment, which is transported by mountain streams in the summer half-year, is a challenge.

In three projects, co-funded by the Swiss Federal Office of Energy, the following topics were or are investigated:

- At the high-head hydropower plant Fieschertal in Valais, the suspended sediment load, hydro-abrasive erosion on the Pelton turbines and reduction of their efficiency were measured over nine years. Based on the data set, empirical prediction models were developed to optimize turbine maintenance as well as the electricity production.

- At the hydropower plant Susasca in Grisons, the sand trap was optimized. Real-time measurements of the sediment levels and a modified flushing procedure contributed to reduce the sediment load of the Pelton turbines and hence to reduce their erosion and maintenance cost.

- In a third project, the so-called fatigue of Pelton runners is studied. When a water jet hits a bucket, the mechanical stress increases and then decreases. After millions of load cycles, a crack may form in the metal. To prevent such failures, methods for monitoring and estimating the residual operation time of the runners are further developed.