Hydrogen combustor for future aircraft

Electrifying long-haul flights is not feasible for the next decades due to the much lower energy density of batteries compared to chemical fuels. A project led by GE, in collaboration with Airbus and ETH Zurich, aims at developing a revolutionary hydrogen propulsion system for a zero-carbon commercial aircraft by 2035. Designing a new combustor is very challenging as hydrogen properties and flames differ fundamentally from those of kerosene.

Together with future production of hydrogen by means of solar, wind or nuclear energy, aircraft fueled with hydrogen are considered the most promising option to decarbonize aviation for ranges of up to 2000 nautical miles (3700 km). The Combustion and Acoustics for Propulsion and Power Systems (CAPS) Laboratory at ETH Zurich will play an important role in a collaborative project with GE, Airbus and Safran Aircraft Engines to develop and test an aircraft engine fueled by hydrogen that should carry passengers in the mid-2030s and producing zero carbon emissions during flight. Ultimately this will lay the foundation to decarbonize the aviation industry.

Test flights with an adapted Airbus A380 are planned to begin mid-decade. For this a modified GE Passport turbofan engine will be mounted on the rear top of the fuselage, equipped with liquid hydrogen tanks but powered by its original four engines, thus forming a flying testbed. This configuration will allow the team to demonstrate the capabilities of this novel, hydrogen-powered engine technology and validate emission targets, including contrails, during flight.

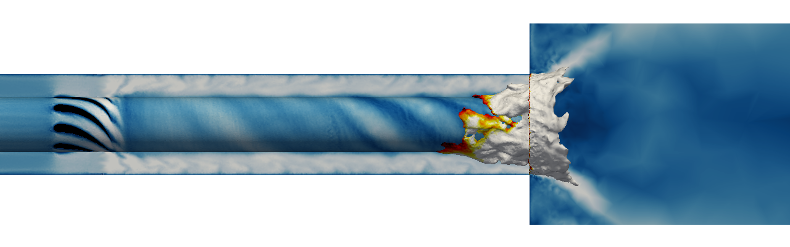

Designing a new combustor for this modified engine is very challenging as hydrogen combustion properties fundamentally differ from those of hydrocarbons. Notably the very high reactivity of hydrogen, poses important challenges to derive a robust design with stable and reliable combustion properties. This is where the CAPS Laboratory at ETH Zurich comes into play within the frame of the Clean Aviation’s HYDEA project co-funded by the EU. CAPS has worldwide unique expertise in testing, advanced diagnostics and numerical analysis for highly reactive unsteady flows. Full-scale prototype burners will be tested in the CAPS Laboratory to verify the robustness of the combustion process and its low nitrogen oxide emissions. CAPS advanced modelling capabilities will then be used to further improve the design.

Research groups, industry partners or related projects

Research articles or reports related to the exhibit

- Flashback limits of turbulent hydrogen flames

- A new combustor concept which can switch from kerosene to pure hydrogen during operation

Thermoacoustic instabilities in aviation combustors models fueled with hydroge: